New OEM 2019+ rear differential gear set, 10/36 tooth straight cut ring and pinion gear set, Timken seals, NTN or IKO pilot bearing , OEM shim kit and OEM bearings along with a new bolt and washer to retain the driveshaft. BRP claims 25% increase in load capacity on this gear set vs the spiral cut xmr final drive units (rear differentials) from 13-18 models. Fits differential part numbers: 705502808, 705502546, 705502178, 705502090 703501031 705501550 705501556 705501557

New OEM 2019+ rear differential gear set, 10/36 tooth straight cut ring and pinion gear set, Timken seals, NTN or IKO pilot bearing , OEM shim kit and OEM bearings along with a new bolt and washer to retain the driveshaft. BRP claims 25% increase in load capacity on this gear set vs the spiral cut xmr final drive units (rear differentials) from 13-18 models. Fits differential part numbers: 705502808, 705502546, 705502178, 705502090 703501031 705501550 705501556 705501557

New Genuine OEM Works on 2014-2020 Commander and Commander Max (2011-2013 Do not have a oxygen sensor) 2013-2018 Maverick and Maverick Max 2017-2020 Maverick X3 and Maverick X3 Max 2018-2020 Maverick Trail 2019-2020 Maverick Sport 2017-2020 Defender and Defender Max If your machine has ECO mode it will have a oxygen Sensor from factory Part number 707600872

- OUT OF STOCK

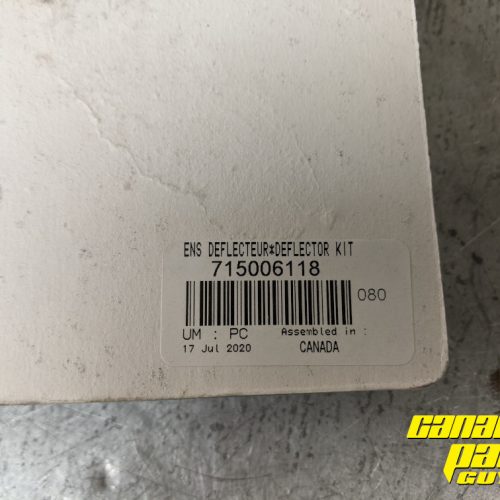

New Genuine OEM Mounting kit sold separately Part number 715003814

New Genuine OEM Mounting kit sold separately Part number 715003814