OEM Air Filter for Gen 1 Outlander and Renegades. Larger style air filter found on 800R machines. OEM part number: 707800288

- OUT OF STOCK

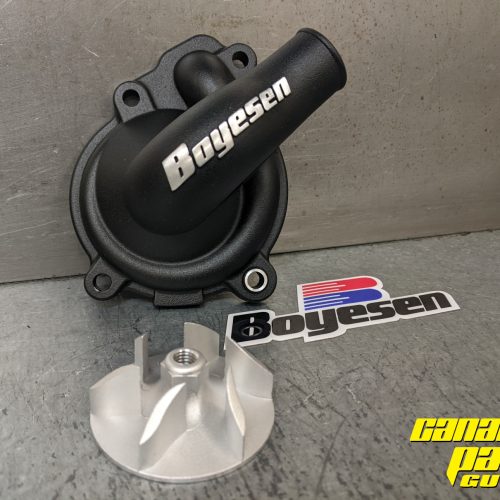

BOYESEN SUPERCOOLER WATER PUMP Cover and Impeller Kit Increased coolant flow at all rpm ranges Patented Nautilus-style impeller for hydrodynamic efficiency Color/Finish: Black, Powder-Coated Material: Aluminum Model: Supercooler Part number 850709 WPK-80AB Replaces OEM 420822750, 420622020 and 420622022 This is the style with the larger output nipple roughly 1 inch in outer diameter.

BOYESEN SUPERCOOLER WATER PUMP Cover and Impeller Kit Increased coolant flow at all rpm ranges Patented Nautilus-style impeller for hydrodynamic efficiency Color/Finish: Black, Powder-Coated Material: Aluminum Model: Supercooler Part number 850709 WPK-80AB Replaces OEM 420822750, 420622020 and 420622022 This is the style with the larger output nipple roughly 1 inch in outer diameter. - OUT OF STOCK

New OEM Can Am tool Designed to make adjusting your shift cable easy Comes with shift lever locking tool to hold the shift lever in neutral while adjusting cable Also comes with the shift plate locking tool which is screwed into the rear cylinder head and the other end locks the shift lever indicator on the gearbox in the correct place. Works on 2011-2020 Commander and Commander Max machines and 2013-2018 Maverick and Maverick Max machines Current part number 529036252 Click here for adjustment procedures

New OEM Can Am tool Designed to make adjusting your shift cable easy Comes with shift lever locking tool to hold the shift lever in neutral while adjusting cable Also comes with the shift plate locking tool which is screwed into the rear cylinder head and the other end locks the shift lever indicator on the gearbox in the correct place. Works on 2011-2020 Commander and Commander Max machines and 2013-2018 Maverick and Maverick Max machines Current part number 529036252 Click here for adjustment procedures - OUT OF STOCK

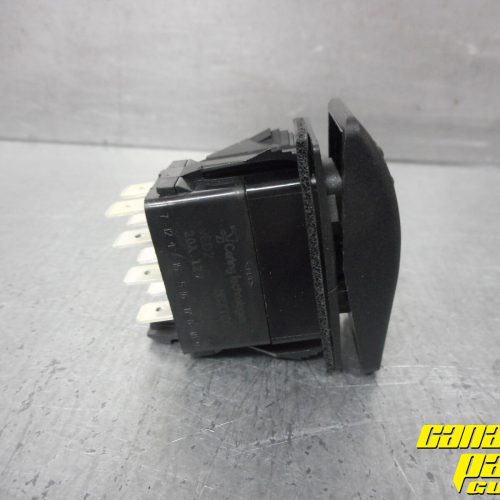

New OEM Can Am Brake Switch Part Number: 705601250 Unsure on fitment? Please ask us we will help!

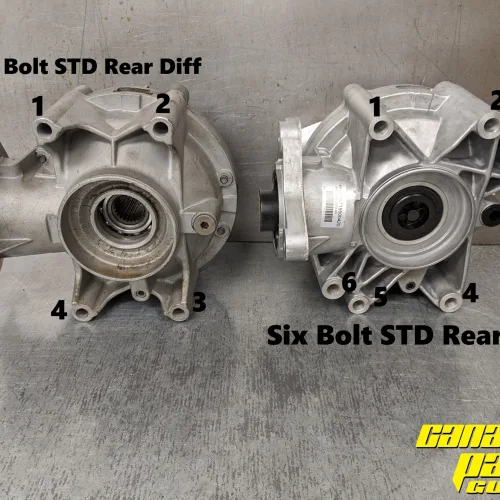

There are a few options for kits, please verify your differential uses this style of gears before ordering!

This will only fit six mounting hole differentials.

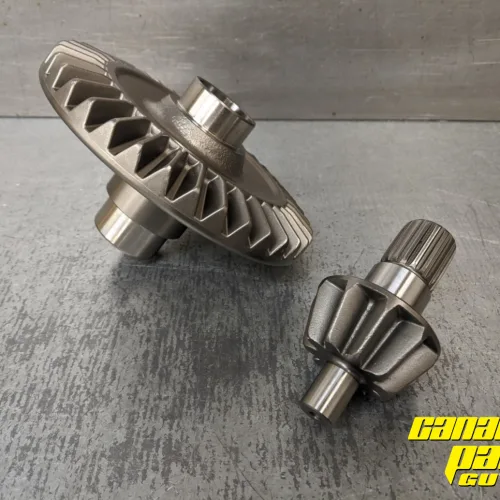

Late G1 Early G2 Standard Rear Differential Ring 36t and Pinion 10t gear set Pinion bolt size is M10, this may be different than what you are replacing.

OEM Rear Differential Gear set 10/36 Ring and Pinion gear set. The gears are straight cut as pictured. This kit should be installed by an experienced technician.

Open up the differential! Check for two bearings total (one on each side) on the ring gear. If you only have two proceed to the next measurement. Measure your outer diameter of your axle seals! They should measure close to 1 3/4? (47mm) To further verify fitment you can measure your pinion pilot shaft, this should be 9/16″ (14mm) The pictures show this very clearly. Please take the time to measure your parts before buying this will save time and restocking fees.

Drive Belt Can Am Fits: 2017-2020 Maverick X3 900HO Turbo R Turbo RR 2017-2020 Maverick Trail/Sport 800R, 1000, 1000R 2016-2020 Defender HD10/HD8

Replaces OEM # 422280651 / 417300383 / 422280654 / 422280652 Gates Part number 48R4289 If you have fitment questions, please ask, we are here to help.

IF YOUR MAVERICK HAS A REAR DRIVESHAFT (OG MAVERICK) THIS BELT WILL NOT FIT.

FEATURES AND BENEFITS

Designed for the most demanding, turbo-charged off-road CVT applications. With Gates proprietary materials and design, G-Force™ RedLine™ CVT belts handle extreme temperatures with excellent heat recovery, while maximizing load and torque capacity - making it one of the most efficient CVT belts currently on the market.- First on the market to utilize Ethylene Elastomer compound to address the needs of larger SxS and high-horsepower ORVs in tough riding conditions.

- Next-generation EE compound offers maximum transverse stiffness and heat resistance, resulting in higher load capacity, higher peak torque capacity, less “heat fade” and less speed loss.

- Delivers 75% greater dynamic axial stiffness on average, up to 50% lower speed losses and better recovery from temperatures up to +170°C (+338°F) without power loss.

- Unmatched Temperature Capability – Runs cooler, resists glazing for better recovery and reduced cracking/chunking out after running at temps exceeding +149°C (+300°F).

- Extended Belt Life – Belt life increased 100-300% versus aftermarket competitive belts in severe duty lab test conditions and in field testing.

- Higher Power Capacity – Reduced speed (rpm) loss by 50% under high loads and increased load capacity by >10% compared to other aftermarket belt.

DON’T BREAK YOUR BELT. BREAK IT IN.

If you don’t break the belt in properly, you’ll find yourself shredding the belt instead of the terrain. In fact, most powersports belt failures can be attributed to improper break-in and clutch adjustment – or not breaking in the belt at all. Follow these steps to ensure the best performance and longest life from your G-Force™ belt.

1. Clean the clutches according to manufacturer specifications and clean the sheaves with a Scotch-Brite™ pad. Remove old belt residue, glazing, oils, and debris with alcohol or acetone on the clutch sheave area. Be sure your breather tubes are free of any belt material (broken belt material gets everywhere)

2. Install and Break It In. Perform two heat cycles (10-15 minutes each) at +27°C (+80°F) at 30-40 mph (2-wheel drive) with cover installed. Bring the belt temperature down to normal operating temperatures, then shut down and let cool for 30 minutes. Repeat the process a second time. If belt installation is at a temperature of +16°C (+60°F) or below, perform two heat cycles in 20 minutes at 30-40 mph (2-wheel drive) with cover installed. Bring the belt temperature down to normal operating temperatures, then shut down and let cool for 30 minutes. Repeat the process a second time. Conservatively run through the entire shift range, without exceeding ¾ throttle. Bring the belt back to normal operating temperature (15 minutes) then shut down and completely cool the belt for 30 minutes. Repeat the process.