Can-am Outlander, Renegade or Commander 500 650 800 1000 6 Bolt HD rear Differential. This is an OEM Canam part used in many Generation 1 atvs. It has the bracket for the rear brake caliper on it. This is an updated version with much more substantial webbing for improved support. Fits: 2006-2011 Outlander and Renegade 500 650 800 800 2012 Outlander MAX 400 500 650 800 2011 2012 Outlander 800XMR 2006-14 Outlander 400 2011-2013 Commander 800 1000 Current Part Number 703501033 Previous Part Numbers 703500892 705502069 705501569 Interchanges with: 705500774 705500822 705501412 705500891 705501093 705501047 705501997

Can-am Outlander, Renegade or Commander 500 650 800 1000 6 Bolt HD rear Differential. This is an OEM Canam part used in many Generation 1 atvs. It has the bracket for the rear brake caliper on it. This is an updated version with much more substantial webbing for improved support. Fits: 2006-2011 Outlander and Renegade 500 650 800 800 2012 Outlander MAX 400 500 650 800 2011 2012 Outlander 800XMR 2006-14 Outlander 400 2011-2013 Commander 800 1000 Current Part Number 703501033 Previous Part Numbers 703500892 705502069 705501569 Interchanges with: 705500774 705500822 705501412 705500891 705501093 705501047 705501997

NEW OEM O-rings and hex bolts to install inner CVT cover on most Can-Am V-twins. Works on 7 and 13 bolt inner covers Part numbers: O-rings - 420430407 and 420631087 old numbers 420430408 420631088 Hex Bolts - 420440207 Also has a nut and washer for 1000 cover installation - 232561434, 224061121 Will come as pictured

NEW OEM O-rings and hex bolts to install inner CVT cover on most Can-Am V-twins. Works on 7 and 13 bolt inner covers Part numbers: O-rings - 420430407 and 420631087 old numbers 420430408 420631088 Hex Bolts - 420440207 Also has a nut and washer for 1000 cover installation - 232561434, 224061121 Will come as pictured- OUT OF STOCK

NEW OEM ignition switch. Part number 710008400 replaces 710002327 710003847 It will work on all 2011 to 2019 Commanders, 2012 to 2016 Generation 2 Outlanders and Renegades and 2013 to 2018 Mavericks. Key sold separately.

SHIPS FREE TO THE LOWER 48 STATES This will replace the functionality of the VISCO Lock in any Can-am Front differential. 2006 to Current including X3. Installs in place of the “spider gears” Will not fit models with an electronic smart lok front differential Very simple to install. One measurement to make. The TORQ Locker is the most advanced, strongest, highest quality automatic locking differential on the planet, proven in the most extreme vehicles from hard-core Rock Crawling, racing the King of the Hammers, Rock Bouncing, Sand Dunes and Mud Drags. To back this all up, Torq-Masters Industries offers an unprecedented 2 year warranty on the TORQ Locker with no tire size, horsepower limits or loopholes. Torq-Masters Industries is committed to building the highest quality locking differentials possible. To be the best, we build with the best, TORQ Locker is 100 percent Made in the USA with 100 percent USA raw materials. Keep it Simple, no air-lines to leak, compressors to fail, cables to adjust or electrical gremlins, the TORQ Locker gives you piece of mind as a reliable, mechanical, automatic locker that can handle any terrain. The TORQ Locker design eliminates and integrates pesky locker components seen in all other automatic drop-in lockers. The spacers are gone and the dowel pins are now machined into the Cam Gears to form key-ways. The innovative design features of the TORQ Locker have three game-changing benefits: No dowel pins to install or fail. The Key-Way design of the Cam gears can’t shear, ever. Easiest Locker on the market to install, no spacers, no dowel pins, one measurement. Best On-Road manners of any automatic locker; the Key-Way design is more forgiving than the rigid dowel pin design. The Key-Way allows for smoother locker engagement. By eliminating the spacers they eliminated the leading cause of the pop some people experience with automatic lockers. Listing is for the TORQ Locker only. Differential carrier shown in pictures is for reference only.

SHIPS FREE TO THE LOWER 48 STATES This will replace the functionality of the VISCO Lock in any Can-am Front differential. 2006 to Current including X3. Installs in place of the “spider gears” Will not fit models with an electronic smart lok front differential Very simple to install. One measurement to make. The TORQ Locker is the most advanced, strongest, highest quality automatic locking differential on the planet, proven in the most extreme vehicles from hard-core Rock Crawling, racing the King of the Hammers, Rock Bouncing, Sand Dunes and Mud Drags. To back this all up, Torq-Masters Industries offers an unprecedented 2 year warranty on the TORQ Locker with no tire size, horsepower limits or loopholes. Torq-Masters Industries is committed to building the highest quality locking differentials possible. To be the best, we build with the best, TORQ Locker is 100 percent Made in the USA with 100 percent USA raw materials. Keep it Simple, no air-lines to leak, compressors to fail, cables to adjust or electrical gremlins, the TORQ Locker gives you piece of mind as a reliable, mechanical, automatic locker that can handle any terrain. The TORQ Locker design eliminates and integrates pesky locker components seen in all other automatic drop-in lockers. The spacers are gone and the dowel pins are now machined into the Cam Gears to form key-ways. The innovative design features of the TORQ Locker have three game-changing benefits: No dowel pins to install or fail. The Key-Way design of the Cam gears can’t shear, ever. Easiest Locker on the market to install, no spacers, no dowel pins, one measurement. Best On-Road manners of any automatic locker; the Key-Way design is more forgiving than the rigid dowel pin design. The Key-Way allows for smoother locker engagement. By eliminating the spacers they eliminated the leading cause of the pop some people experience with automatic lockers. Listing is for the TORQ Locker only. Differential carrier shown in pictures is for reference only.

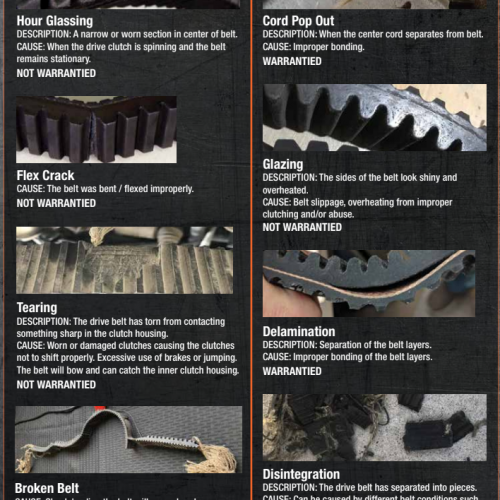

SHIPS FREE TO THE LOWER 48 STATES Fits all 500, 650, 800, 800R, 570, 850, 1000, 1000R and 1000R turbo Mavericks Outlanders, Renegades, and 2020 & Prior Commanders. Replaces OEM part numbers 715000302, 422280360, 715900212, and 422280364. This will not fit: Defenders, Maverick X3 or Maverick Sport/Trail Gates Part number 30R3750 Do not confuse this with the carbon or standard g-force, this is the newly developed for the 2020 season.DON’T BREAK YOUR BELT. BREAK IT IN.FEATURES AND BENEFITS Designed for the most demanding, turbo-charged off-road CVT applications. With Gates proprietary materials and design, G-Force™ RedLine™ CVT belts handle extreme temperatures with excellent heat recovery, while maximizing load and torque capacity ― making it one of the most efficient CVT belts currently on the market.

SHIPS FREE TO THE LOWER 48 STATES Fits all 500, 650, 800, 800R, 570, 850, 1000, 1000R and 1000R turbo Mavericks Outlanders, Renegades, and 2020 & Prior Commanders. Replaces OEM part numbers 715000302, 422280360, 715900212, and 422280364. This will not fit: Defenders, Maverick X3 or Maverick Sport/Trail Gates Part number 30R3750 Do not confuse this with the carbon or standard g-force, this is the newly developed for the 2020 season.DON’T BREAK YOUR BELT. BREAK IT IN.FEATURES AND BENEFITS Designed for the most demanding, turbo-charged off-road CVT applications. With Gates proprietary materials and design, G-Force™ RedLine™ CVT belts handle extreme temperatures with excellent heat recovery, while maximizing load and torque capacity ― making it one of the most efficient CVT belts currently on the market.- First on the market to utilize Ethylene Elastomer compound to address the needs of larger SxS and high-horsepower ORVs in tough riding conditions.

- Next-generation EE compound offers maximum transverse stiffness and heat resistance, resulting in higher load capacity, higher peak torque capacity, less “heat fade” and less speed loss.

- Delivers 75% greater dynamic axial stiffness on average, up to 50% lower speed losses and better recovery from temperatures up to +170°C (+338°F) without power loss.

- Unmatched Temperature Capability – Runs cooler, resists glazing for better recovery and reduced cracking/chunking out after running at temps exceeding +149°C (+300°F).

- Extended Belt Life – Belt life increased 100-300% versus aftermarket competitive belts in severe duty lab test conditions and in field testing.

- Higher Power Capacity – Reduced speed (rpm) loss by 50% under high loads and increased load capacity by >10% compared to other aftermarket belt.

If you don’t break the belt in properly, you’ll find yourself shredding the belt instead of the terrain. In fact, most powersports belt failures can be attributed to improper break-in and clutch adjustment – or not breaking in the belt at all. Follow these steps to ensure the best performance and longest life from your G-Force™ belt.

1. Clean the clutches according to manufacturer specifications and clean the sheaves with a Scotch-Brite™ pad. Remove old belt residue, glazing, oils, and debris with alcohol or acetone on the clutch sheave area. Be sure your breather tubes are free of any belt material (broken belt material gets everywhere)

2. Install and Break It In. Perform two heat cycles (10-15 minutes each) at +27°C (+80°F) at 30-40 mph (2-wheel drive) with cover installed. Bring the belt temperature down to normal operating temperatures, then shut down and let cool for 30 minutes. Repeat the process a second time. If belt installation is at a temperature of +16°C (+60°F) or below, perform two heat cycles in 20 minutes at 30-40 mph (2-wheel drive) with cover installed. Bring the belt temperature down to normal operating temperatures, then shut down and let cool for 30 minutes. Repeat the process a second time. Conservatively run through the entire shift range, without exceeding ¾ throttle. Bring the belt back to normal operating temperature (15 minutes) then shut down and completely cool the belt for 30 minutes. Repeat the process.

Can-Am Rear Transmission Seal. Fits Large Gear Boxes, Standard and Low Ratio. Brand New OEM Seal OUTPUT SHAFT SEAL found on rear of gearbox, just in front of the rear driveshaft. This is the seal that goes on the rear, where the rear driveshaft goes out to the rear differential. If you are unsure if this is correct, please measure your current seal. If you get close to these specs it should work, the other option is much smaller in outer diameter. 72mm outer diameter 35mm inner diameter Current part number: 420831955 420831956

Can-Am Rear Transmission Seal. Fits Large Gear Boxes, Standard and Low Ratio. Brand New OEM Seal OUTPUT SHAFT SEAL found on rear of gearbox, just in front of the rear driveshaft. This is the seal that goes on the rear, where the rear driveshaft goes out to the rear differential. If you are unsure if this is correct, please measure your current seal. If you get close to these specs it should work, the other option is much smaller in outer diameter. 72mm outer diameter 35mm inner diameter Current part number: 420831955 420831956

SHIPS FREE TO THE LOWER 48 STATES Fits all 500, 650, 800, 800R, 570, 850, 1000, 1000R and 1000R turbo Mavericks Outlanders, Renegades, and 2020 & Prior Commanders. Replaces OEM part numbers 715000302, 422280360, 715900212, and 422280364. This will not fit: Defenders, Maverick X3 or Maverick Sport/Trail World’s Best Belt Line

SHIPS FREE TO THE LOWER 48 STATES Fits all 500, 650, 800, 800R, 570, 850, 1000, 1000R and 1000R turbo Mavericks Outlanders, Renegades, and 2020 & Prior Commanders. Replaces OEM part numbers 715000302, 422280360, 715900212, and 422280364. This will not fit: Defenders, Maverick X3 or Maverick Sport/Trail World’s Best Belt Line- Latest generation heavy-duty, high-twist Aramid Fiber cord for HIGH HORSEPOWER TENSILE LOAD requirements. Making it the strongest belt on the market.

- Highest shock load rating to date being able to withstand the power of the 400hp machines.

- Increased top cog pressure load design that increases sidewall rigidity, prevents top cog bowing, but still allows for increased rotational flexibility.

- Bottom cog uses HIGH MODULOUS RUBBER COMPOUND (BZX1) for better heat resistance and heat dissipation.

- Bottom cog is impregnated with short Aramid Fibers for better belt-to-sheave adhesion and reduced overall belt temperature.

- Latest bottom cog design for greater rotational efficiency at full shift.

- Precision ground sidewall angle (SCUFFING) for smooth engagement, increased power transfer and lower operating belt temperature.

- Aramid Fiber cord, versus polyester, wraps over bottom cogs for increased bottom cog strength.

- Increased cord pop-out resistance.